Txinako altzairu industriak hazkunde nabarmena izango duela aurreikusten da datozen urteetan, % 1-4ko hazkunde-tasa egonkorra espero baita 2024-2026 bitartean. Eskariaren gorakadak aukera onak eskaintzen ditu material berritzaileak erabiltzeko ekoizpenean.C korneta.

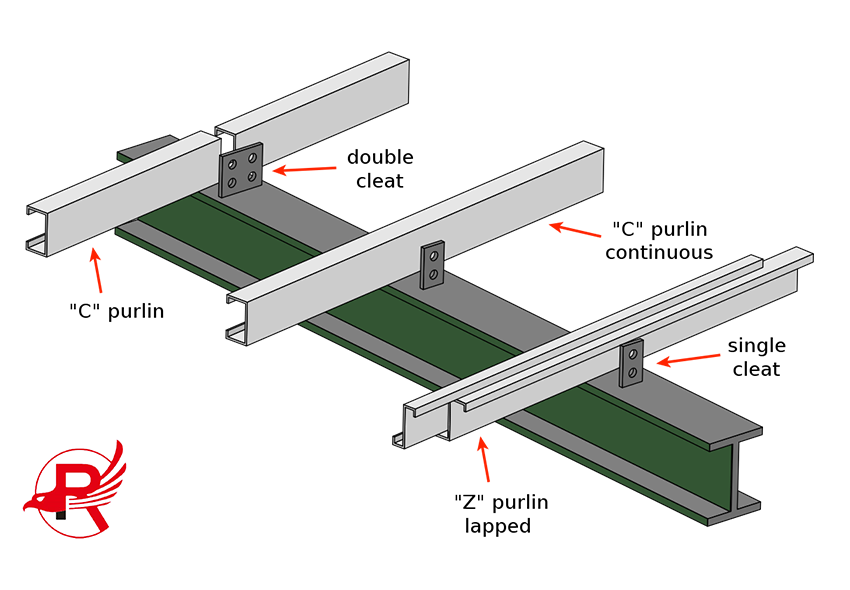

KonbentzionalaC-Purlin kanalakNormalean altzairu konbentzionalez egiten dira eta hamarkadetan zehar eraikuntza-industrian oinarrizko elementu izan dira. Hala ere, materialen berrikuntzaren paisaiaren bilakaerak errendimendu hobetuko alternatiba aurreratuen garapenerako bidea ireki du. Material berritzaile hauek, hala nola erresistentzia handiko aleazioak, zuntz konposatuak eta polimero aurreratuak, C kanaleko altzairuzko kornetak ekoizten ari dira.

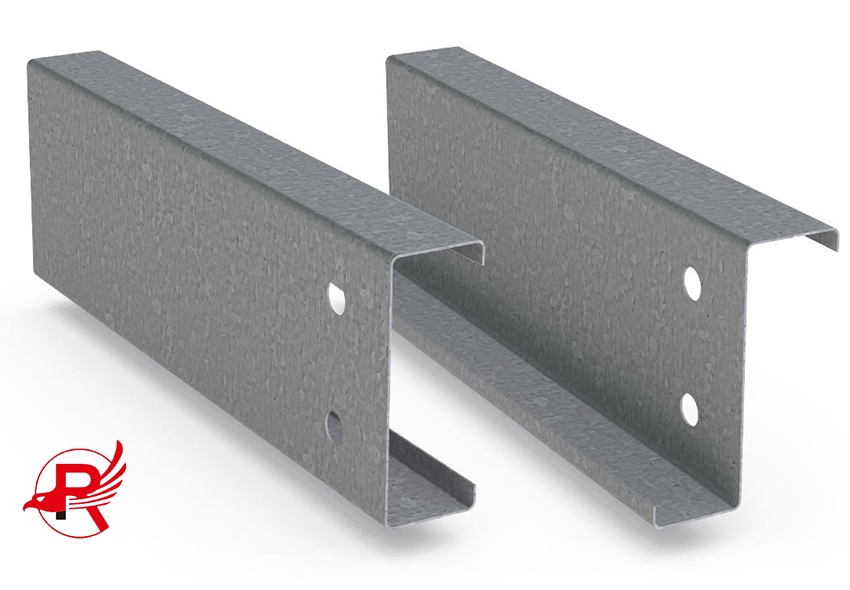

Material berritzaileak erabiltzearen abantaila fabrikazioanC Purlin Altzairu GalbanizatuaPisua nabarmen murrizten da egitura-osotasuna arriskuan jarri gabe. Horrek ez du instalazio-prozesua errazten bakarrik, baita kostu orokorrak aurrezten eta eraikuntza-proiektuen eraginkortasuna hobetzen ere laguntzen du. Gainera, material hauen korrosioarekiko erresistentzia bikainak zerbitzu-bizitza luzea bermatzen du, klima tropikaleko eskualdeetarako aukera aproposa bihurtuz.

Material berritzaileen erabileraC ataleko kornetaindustriak iraunkortasunean eta ingurumen-erantzukizunean duen gero eta arreta handiagoarekin bat dator. Birziklagarriak eta energia-eraginkorrak diren ingurumen-materialak erabiliz, fabrikatzaileek beren karbono-aztarna murrizten eta praktika jasangarriak sustatu ditzakete altzairu-industrian.

Helbidea

Bl20, Shanghecheng, Shuangjie Street, Beichen Barrutia, Tianjin, Txina

Posta elektronikoa

Telefonoa

+86 13652091506

Argitaratze data: 2024ko uztailak 25